As part of a detailed experiment ‘to measure how accurately we measure things’, Chris Adams of Flylogix found himself living the high life.

“When we wrote out Flylogix’s values, the conclusion was that Flylogix is ‘brave, different and determined’. At the time, the ‘bravery’ was, as far as we were all concerned to do with being bold and willing to take risks from a business and technology point of view.”

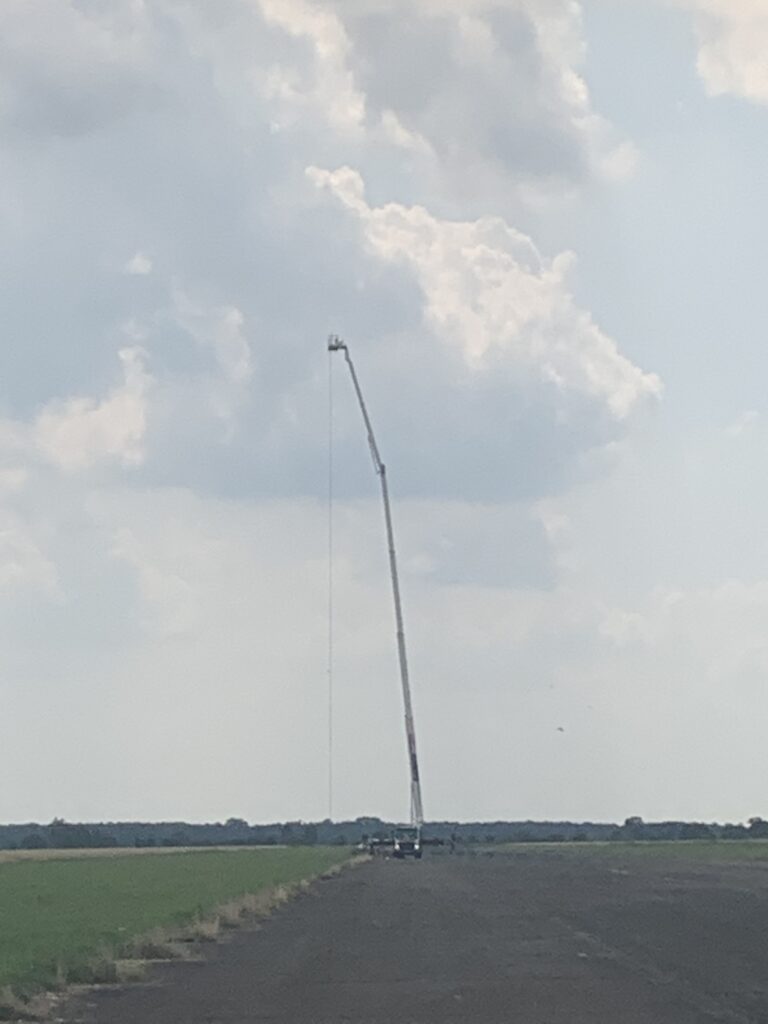

“In July (2021) I found myself dangling 60 metres above the runway of a small airport in Northamptonshire in a one-metre square ‘bucket’, suspended from the second-highest crane in the UK.”

“Well, this is certainly a bit different, I thought. But we are – as a business – absolutely determined to prove the ability of our unmanned aircraft to provide the most accurate, sustainable, safe solution to offshore surveys. So if this is what it takes ….”

”You can’t manage what you can’t measure.

Flylogix is helping energy companies to meet environmental targets by unprecedented accuracy in the measurement of emissions.

“Since spring 2021, we have been running unmanned vehicle flights to offshore energy assets, on behalf of a group of energy producers, including BP, Total, Equinor, Harbour Energy and Shell as part of a longstanding project which is being co-funded by the Net Zero Technology Centre to accurately measure methane emissions offshore.”

“This is an absolutely vital project, because – with aggressive targets for emissions reduction – all of these energy companies are acutely focused on the principle that, to effectively manage levels of emissions, you have to have a detailed picture of what is happening. As the saying goes, ‘you can’t manage what you can’t measure’.”

“Measuring the methane emissions of an offshore asset such as an oil platform is incredibly difficult. But through our determined approached, and working with SeekOps, our industry-leading partner in gas sensing, we believe we have the answer to that challenge.”

“So, first of all we have to measure our own measurements. This initial calibration and demonstration of repeatability is critical to the credibility of the technique, and will enable us to say unequivocally to the energy companies – ‘if we tell you that you’ve reduced your methane emissions from ‘x’ kg per hour, to ‘y’ kg per hour, there’s no guesswork or estimation involved – it’s based on empirical data.”

“The only way to do that was to create a completely controlled environment, in which we released a small but known emission source into the air. We then used our UAV and software to measure the emissions in the air. That enabled us to compare known data with measured data.”

“Systems for measuring emissions around an offshore oil or gas platform have, to date, been expensive, hazardous, haphazard and, perversely, often environmentally-unfriendly. Using a drone to measure emissions is less expensive, green, safe, and – we are close to proving – incredibly accurate.”

How to simulate an offshore platform ….. in the Northamptonshire countryside.

“Our objectives were: to create a set-up which simulated an offshore platform, to release a controlled amount of methane, to mimic a flight around our ‘oil platform’; to pick up hundreds of thousands of data points in that flight; and then to compare our findings with what we had released.”

“The answer was a small, private airport – to mimic the large, flat area of water that an offshore platform is surrounded by. We then hired a 60-metre tower crane – the second highest in the UK to replicate the height of an offshore platform – at the top of which we had a small and accurately metered emission source.”

“Environmental conditions are a key part of the calculations so we also wanted to measure wind speed at different altitudes. On the ground was fairly straightforward. On the aircraft could be done by the onboard equipment. And at 60-metres off the ground it could be measured with the placement of an anemometer in the bucket. The only issue was that it had to be set up to face due north, and the only way to do this was for someone to go up in the bucket and calibrate it manually, which was how I (Chris) found myself suspended above Deenethorpe airport.”

“The UAV carrying the measuring equipment then had to fly a range of spirals around the crane, in varying flight patterns and speeds, across three days of testing. We are now in the process of analysing the data that we recorded.”

“For Flylogix it’s been vitally important for us to carry out this project, because from here on we can look our clients in the eye and tell them that, when we measure their emissions, they are getting the most accurate and credible data they have ever had.”

“That – in all seriousness – is the bravery and the determination that we talked about when we established Flylogix. To make quantum leaps of progress we knew we would have to make ourselves vulnerable, to take risks, to expose ourselves to the possibility of failure.”

“But we knew that the end-game in this is for energy companies to tackle environmental issues head-on, armed with accurate, robust, reliable information.